Denim is a fabric synonymous with comfort and style and hence enjoys widespread global popularity. But few people know that it is also one of the most water-intensive and polluting fabrics to produce.

India is the world’s third-largest denim producer. At the same time, it faces growing water scarcity. That makes the environmental cost of denim especially hard to ignore.

India’s Denim Belt and the Water Crisis

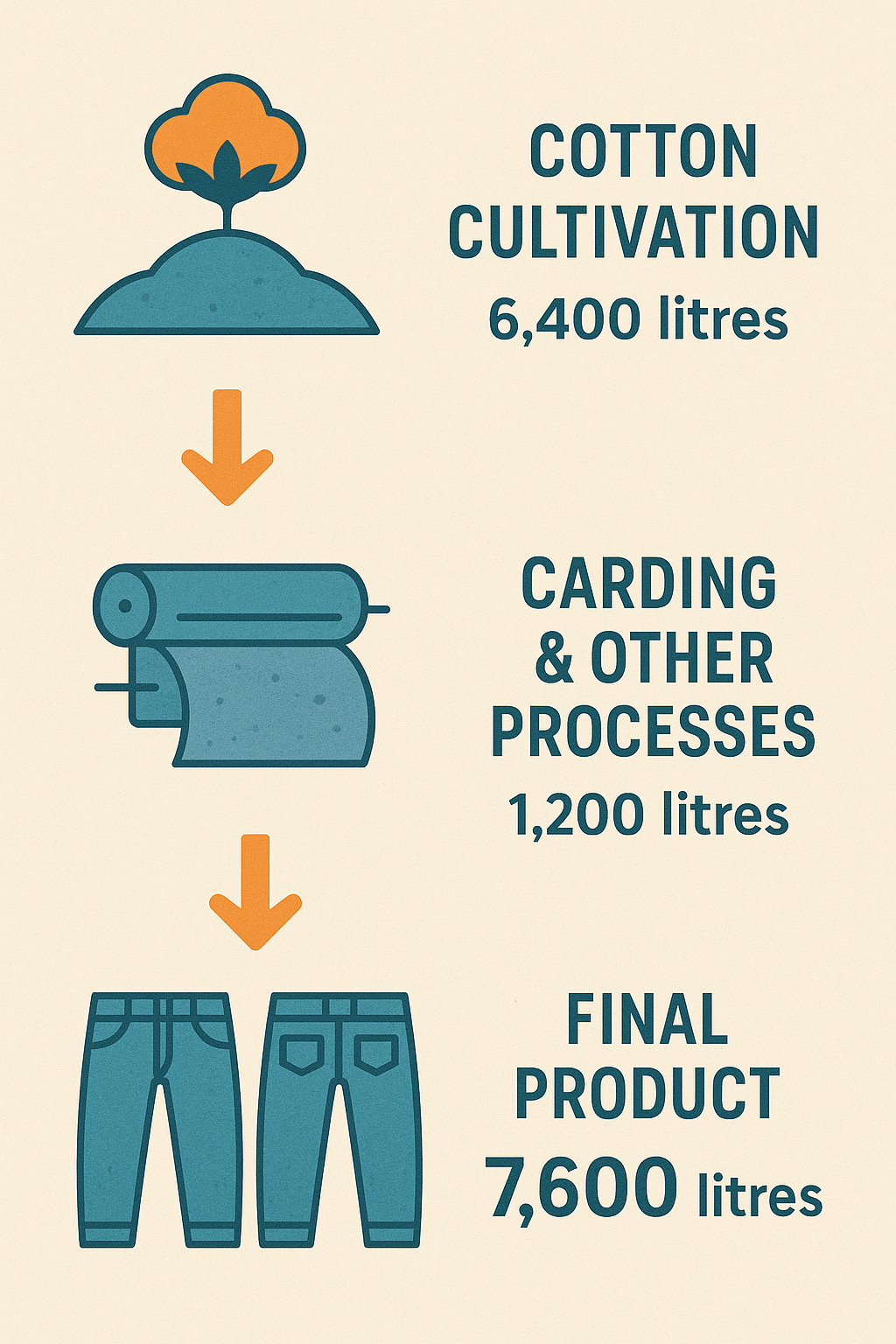

Producing a single pair of jeans can require anywhere between 3,781 to 7,600 litres of water. Cotton farming is by far the most water-hungry stage of the denim lifecycle.

For example, cotton farming in India can take up to 22,500 litres of water per kilogram of cotton. And India’s reliance on water-intensive irrigation methods, especially amid rivers drying up, polluted lakes, and erratic monsoons, makes the issue worse.

States like Gujarat, Andhra Pradesh, and Telangana, that account for most of the denim manufacturing in the country have reported significant loss in ground water level, river drying and salinity in water bodies.

But the problem doesn’t end in the field. Add to that the water intensive and chemical-laden processes in factories, and denim production becomes a full-spectrum threat to water resources, ecosystems, and even human health.

Pollution Along the Supply Chain of Jeans

The environmental toll intensifies during the dyeing and finishing stages.

The denim industry’s shift from plant-based to chemical indigo dyes, done decades ago to cut costs, has brought synthetic substances containing volatile organic compounds and heavy metals in the ecosystem. These often seep into local water bodies, harming aquatic ecosystems and communities that depend on them.

India is both a major user and producer of synthetic dyes. While some companies are showing interest in bio-based or natural dyes, producing and adopting them at scale is still a challenge, majorly due to the costs.

However, on the positive side, some denim manufacturers have begun changing their production processes. Innovations like foam dyeing, laser finishing, and ozone treatments are gaining traction. Companies like Arvind Limited and Vishal Fabrics say their factories have significantly reduced water and chemical use through these methods. Others, such as KG Fabrics and Nandan Denim claim to reuse a large portion of their water through liquid discharge effluent treatment plants.

Worker Health in the Denim Industry: The Hidden Casualty

It’s not just the environment that suffers. The factory floor brings its own risks.

The use of chemicals like formaldehyde, chlorine, and sulfur compounds during bleaching, dyeing, and finishing has exposed workers—especially in low-cost manufacturing hubs—to serious health issues. These include asthma, chronic bronchitis, eye irritation, and even chemical burns.

One particularly dangerous technique, sandblasting, used to give jeans a distressed look, has been directly linked to silicosis, a fatal lung disease. Although banned in countries like Turkey and the UK, sandblasting is still not officially banned in India.

Efforts to Fix the Denim Industry: What’s Working and What Isn’t

Water stress is not just about insufficient availability. Rising salinity in water bodies, sudden floods driven by climate change, and shifting weather patterns make cotton farming even more difficult.

Several initiatives have emerged to address the situation. Programmes like Better Cotton and Cotton Connect have been working to train and support Indian cotton farmers in reducing water use. According to their own reports, they’ve made measurable strides in regions where they operate.

Government efforts like Pradhan Mantri Krishi Sinchayee Yojana (PMKSY) are pushing awareness and subsidies for micro-irrigation. The 2025 Agriculture Budget also includes targeted cotton production missions focused on efficient irrigation systems.

However, many of these initiatives face challenges in implementation. Without wider adoption, the risk to India’s water bodies, including underground water reserves, will continue to grow.

Ticking clock and the Road Ahead

The Indian denim industry is expected to reach nearly ₹91,894 crore by 2028. But if the industry continues to grow without reforming its practices, it may accelerate environmental collapse.

Thankfully, the public push for sustainability is forcing the industry to respond and several brands are shifting towards sustainable manufacturing. But for many local manufacturers, the road is far from smooth. Fluctuating cotton prices—caused by crop failure, variable yields, and unpredictable climate conditions—continue to put strain on both supply and affordability.

While large manufacturers are revisiting their processes, when it comes to shifting the denim production system in India to sustainable footing, we’re only at the beginning. The denim industry’s efforts are nascent, fragmented, and struggling to keep pace with the scale of the challenge.

And since climate change isn’t a distant threat anymore, and many of India’s water bodies are dangerously close to the brink; A systematic overhaul of the industry is an urgent requirement. Because if denim continues to be produced the way it has been, it may leave a stain on India’s sustainability strides.